Want higher yields? Grow light movers could be quite literally the right track to getting the most out of your lights, your grow space, and your plants. We tell you what a grow light mover does, why you might need one, and then review the best grow light movers currently available.

VEVOR Light Rail Mover 10.8 ft Grow Light Mover Kit with on/Off Button

Higher yields, more even coverage, lower lighting costs

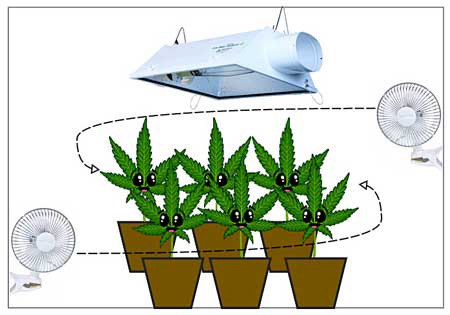

Grow light movers ensure that light is distributed evenly across the whole grow space to penetrate further beneath the canopy and reach more leaves on your plants.

As the name suggests, they do this by moving your lights constantly back and forth across your grow space along a track or rail (or some types have a circular motion). Not only that but…

Because your lights are now constantly on the move, you can now get them even closer to your plants without worrying about hotspots, light burn, or excess heat—which means your plants can absorb even more of the photons your grow lights are throwing out.

In other words: Healthier plants, more bud sites, more energy stored up in the leaves ready for flowering, higher yields—and not to mention much better bang for your buck!

And there are other benefits too…

In this article, we’ll explain more about how light movers work, what types are available, why they outperform static light sources, and what to look for when buying.

And if you’ve only seen light rails used in commercial grows before, don’t worry. They’re not just for commercial growers. Home growers can benefit too. Some can even be used in a grow tent.

What are grow light movers?

The most basic type of grow light mover is a single rail or track attached to the ceiling of your grow space, along which your attached grow light travels constantly and repeatedly back and forth. (It could also be attached to a frame above your garden, or to your grow tent frame.)

However, you may well have already spotted a potential problem with that oscillating motion…

Let’s say the light does a complete back and forth along the rail. Plants in the middle of the footprint will still have received a bit more light than those at either end—i.e. exactly the main problem you installed it to solve in the first place!

This is why any decent light mover also has a delay built in.

In other words, to compensate for that extra time in the middle, the lights pause briefly at each end of the rail. If you’re using a model where the length of the rail or how far the light travels is adjustable, the delay time is usually also adjustable.

However, single tracks are not the only option available.

Nor are linear tracks or rails.

What types of light movers are available?

Linear light movers are the most popular and widespread. Many can move more than one light on the same track or rail.

Equally some growers may set up multiple parallel tracks.

But given the home growing laws in most states, most home growers aren’t likely to need more than one.

As we mentioned above, the other main type of light mover has a circular motion, somewhat like a ceiling fan. The light or lights rotate on the end of an arm or arms. Alternatively, the mover might spin 180 degrees in one direction, then back again.

Rotating, circular, or rotary grow light movers, however, can be a little more difficult to set up.

For one thing, there are the trailing power cords from each light, which you’ll have to make sure are correctly routed to ensure safe, tangle-free rotation. Instructions on that are usually provided of course, but it’s still easy to make a mistake here.

Why use a grow light mover?

In short, to get much more out of your existing setup.

A light mover can significantly extend the footprint of your existing light, improve penetration below the canopy, ensure more and better light reaches all parts of the grow space and can ultimately increase yields by as much as 20%.

They can also save you some money in the short and long term.

For instance, even if you take manufacturer claims with a big pinch of salt, you can see how significantly extending the footprint could save you the expense of buying an extra light or a bigger light.

In addition, higher yields, more efficient use of space, and more efficient use of your light(s) should lead to lower running costs in the long term.

Finally, there are some major disadvantages to growing indoors with a static light source vs. growing outdoors with natural sunlight. Which using grow light movers can eliminate or greatly reduce.

Light movers vs. stationary grow lights

Grow lights, of course, are used in indoor grows to replace the sun.

However, unlike grow lights, the sun is not a static light source; it changes position constantly throughout the day. Consequently, sunlight reaches outdoor cannabis from all sorts of angles and directions.

This means a lot more of an outdoor plant will receive good quality light during the course of a day, and a lot less of the plant will spend time in shade, compared to a cannabis plant grown indoors.

A fixed light source, on the other hand, can struggle to sufficiently nourish the lower parts of the plant. Unless you use plant training methods to expose more of it to the light.

Also, plants at the edge of your grow space get less intense light and consequently will tend to stretch inward toward the center. Growth can be very uneven.

And these are not the only problems with a fixed light source…

Hotspots and shade

Both HID and LED grow lights can suffer from hotspots—areas of coverage that are much more intense (or even too intense).

With an HID that would be the area directly below the bulb.

And with LEDs, it can be small areas directly below each chip. (LED footprints are pretty even these days, compared to early models, but this can still be an issue to a small extent. Especially with cheaper lights.)

These intense hotspots necessitate hanging the lights higher above your plants than is strictly optimal, reducing both light and energy efficiency.

By the same token, both types of grow light also suffer from lower intensity areas (at the edges) and areas constantly in shade. Which can lead to poor growth beneath the canopy and stretching. (More on that in the next section.)

A further significant ‘hotspot’ problem with HID lights is the high amount of heat they give off—especially directly below the bulb. This heat means hanging them still higher up and reducing light and energy efficiency even further. (LEDs, however, run much cooler.)

Movement is the solution

A light mover evens out both kinds of hotspots—no part of the plant stays too long under either intense light or intense heat. Light and heat are distributed much more evenly across the whole grow space.

Meaning you can hang your lights much closer to your plants without overheating them or causing light burn—i.e. parts of the plant receiving more photons than they can absorb. The closer to the plants your lights are, the greater the number of photons they emit will actually reach your plants. And the more value you’re getting out of them.

An additional benefit: Spreading the heat also creates better airflow, which is great for plant health.

So that’s more energy the plants can store up for flowering, more quickly. Healthier plants. And ultimately, higher yields.

Light movers save money

Since your plants will receive their optimal daily light intake—or Daily Light Integral (DLI)—more quickly with a light mover, you may even be able to reduce running costs by running your lights for fewer hours per day.

Or you might downgrade to a less powerful lamp and save running costs that way.

Faster growth rate also equals shorter grow times.

Add those benefits to higher yields and being able to extend your footprint without purchasing an extra light, and you can see how a light mover could pay for itself in the short and long term.

Red to far-red ratio

As you likely already know, plants don’t just absorb light and store it as energy. They also react to it. For instance, by growing in the direction of the light source.

In particular, they respond in various ways to the ratio of red light to far-red light wavelengths they receive.

A plant or part of a plant in shadow gets a low red to far-red ratio. From this signal, it ‘knows’ to stretch, to grow taller, to move its leaves closer to the light.

With a static light source, shadow patterns don’t vary.

With a moving light source, however, the shadow is always shifting. The angle of light is constantly changing.

Meaning the average ratio of red to far-red all parts of the plant receive is naturally a lot higher than with a stationary light. Leading to less stretching, less space between nodes, stronger, thicker stems, and more even growth.

In short, much healthier, more even growth, and more penetration below the canopy.

Finally, another benefit of a moving light source and so-called ‘shadow shifting’ is that you can grow your plants a little closer together, allowing for more efficient use of your grow space.

Are there other advantages?

We’ve explained the main advantages of a light mover vs. a fixed light source in detail above. Now here’s the short version, plus a few extras, summarized in bullet points for easier scanning:

- More even coverage

- No hotspots

- ‘Shadow shifting’ means no parts of the plant in constant shade, better red to far-red ratio, less stretching for light

- More even growth and more uniform canopy height

- Better heat management and environmental control

- Helps alleviate the biggest problems with HID lights

- Better airflow and decreased fungal growth

- Hang lights closer to your plants

- Better penetration

- Plants receive more and better light

- Get better value and performance from your existing light

- Or maybe even use a less powerful light and get the same results for lower running costs

- Faster growth rate and shorter grow cycles

- Can grow plants closer together to get the most from a tight grow space

- Extend your light’s footprint by around 30% horizontally

- May be able to avoid buying a second light

- More of the plant exposed to light

- More energy stored up in the leaves before flowering starts

- More bud sites

- Healthier plants

- Higher yields—as much as 20% higher

- A moving source more closely mimics the sun

- Cost savings over the long term—around 20% compared to stationary HIDs

Are there any drawbacks?

The main question to consider here is:

Are you any good with DIY?

If assembling a grow tent is about the limit of your comfort zone, or you don’t have much access to the right tools, a light mover might not be for you.

However, if a bit of cutting, drilling, and measuring doesn’t faze you, great—that’s the major dealbreaker taken care of here.

However, there are a few other points that are still worth considering:

- Some movers are noisy—not ideal if stealth’s a concern

- Can take quite a bit of experimentation and calculation to find the best delay times and hanging height above your canopy

- All plants need to be at the same growth stage when it’s installed—plants at different heights will cause problems for pretty obvious reasons—so probably not an option mid-grow

- Not suitable for all grow spaces, especially very small ones

- If you already have a short grow space, installing a light mover will effectively lower the ceiling even further. On the other hand, they do allow you to hang your lights closer to your plants. So make sure to do the math first

- You’ll need to find another outlet to plug it into.

We could also have mentioned that a light mover is another thing drawing power… But the power draw is actually pretty minimal. And as we’ve already discussed, those costs are likely to be more than offset by other advantages.

Finally, as obvious as it sounds, check that the power cord on your light is long enough that your light can travel back and forth without coming unplugged!

What to look for in a grow light mover

Here are the main questions to ask when evaluating which light mover to buy:

- Is there a delay?

The best light movers feature a delay. A linear light mover without a delay is still better than a static light if that’s all you can afford right now. But coverage won’t be as even.

- Can I shorten the rail or run length? How?

In some cases, the track might be modular. In others, you can set how far along the rail the light will travel. Or you might have to cut the rail down to the size you need.

- If length is adjustable, is the delay adjustable?

Different lengths of rail will require shorter or longer pauses at each end.

- If I decide to extend my grow space at some point, can I extend the track or add lights?

Some kits allow extra track to be added, or endpoints to be adjusted. Some make it easy to add extra lights to the existing track. Rotary light movers often come with different arms and/or arm configurations that can be added to the same fixture as needed, depending on how many lights you want to use. The best grow light mover kits are highly customizable.

- How heavy are the lights I want to use? How heavy is the light mover?

Can the mover carry your lights? (Most will carry plenty of weight, but it’s still worth checking.) And most importantly, can the ceiling/beam/frame you’re attaching it to take the combined weight of the light(s) and mover?

- How noisy is it?

Are you stealth growing? Or just not fond of noise? Some models are much quieter than others.

- What’s the motor speed? Is it variable?

If the track length is variable, you may need to vary the speed the light travels up and down it too, so as not to keep your plants waiting too long for the light to return. Equally, having a higher speed setting could allow you to use a more intense or hotter light without sacrificing closeness to the canopy. This isn’t quite as important a feature, however, as the delay.

- If you’re buying a rotary model, what area can it cover?

Naturally, rotary models have a fixed circumference. More powerful lights may expand that, but a limit will be reached.

- Is it suitable for a grow tent? Can you get a grow tent adapter?

Not all movers can be attached to a grow tent. However, some are more flexible. While the default is often still to attach it to a ceiling, grow tent adapters or frames may be available.

One final tip:

With light movers, it’s worth bearing in mind that higher prices tend to translate into higher quality materials, better build quality, and greater durability.

In cheaper light movers, for instance, cheaper bearings are used in the tracks and can wear out more quickly.

Can I get a light mover instead of a second light?

Maybe.

First of all, it depends on the size of the area you want to cover. You might well be able to grow an extra plant or two just by adding a light mover.

But pay attention to how much the manufacturer claims the mover will extend your light’s footprint. For instance, one major brand claims 30% more horizontal area per grow light.

And don’t try to move a grow light too far.

If you have one light on too long a track, you risk making plants wait an unhealthy amount of time for light to return.

Based on the 30% rule of thumb, a couple of feet of movement in total is recommended for a smaller light, for example. (That may not seem much. But remember, half of the grow light will extend beyond the end of the track—and its footprint even further.) Three feet would be realistic for an average size light. A four feet run could work for the largest lights.

Finally, if maximum yield and reduced grow time is the main priority, and if you can afford it, then it could well be worth investing in both a second light and a light mover.

What are the best grow light movers?

Now you know all about the types of grow light movers available, the pros and cons, and what to consider when choosing, let’s take a look at some of the best grow light movers currently available.

We favor the simplicity, flexibility, and versatility of linear grow light movers, so we’ll focus on those for our choices.

In addition, we’ll be bearing in mind readers with different sizes of grow space and different wallet sizes. And we’ll be sticking to what’s widely available in the US (which rules out Jupiter II light movers, for instance).

So hopefully all of you will find a suitable option here.

And if you don’t, just leave us a message in the comments and we’ll try to help!

Best Entry-Level Light Mover System

In truth, there is really only one big name in grow light movers at present: LightRail from Gualala Robotics.

LightRail 3.5 IntelliDrive Kit

- Light Rail performs over many years like a workhorse with the power and endurance for any light at any weight. Beware of cheaply made imitations.

- Light Rail, solidly made in the USA. manufactured by Gualala Robotics for continuous-use endurance, with instrument quality and commercial standards. Self-clutch drive design for automatic traction control, advanced digital control circuitry.

- Includes Light Rail 3.5 IntelliDrive motor, two-piece 6 ft 6 in rail, adjustable travel distance, adjustable time delay. Compatible with North American electrical.

- Light Rail, exclusively able to move the larger grow lights, and that is with the Light Rail RoboBar, purchased separately.

- Light Rail has these electrical details c csa us or ce, and flammability proof ul 5 vb, and is rohs compliant, safety standards unique to the Light Rail brand.

- Much better yields when our grow lights move because more leaf area is reached with better light, so no hot spots and no shadow patterns. Plus we can cover significantly more area per grow light, and that's with robotic efficiency.

Copycats and budget options exist (see below), but most of them are virtually identical to each other, and a number of lesser brands seem to have fallen by the wayside in recent years.

Why? Well, LightRail movers are just better. Period. Higher quality, USA-made, versatile, flexible, solid, and hard-wearing.

And they’re affordable.

So for many growers, even the existing cheapo, generic systems aren’t that attractive. While you save a bit of extra cash short term, the trade-off in quality and product lifespan just isn’t worth it for most.

Because one of the big advantages of LightRail systems is that they’re made to last—in every way. As well as being hard-wearing, they’re also easily expandable and upgradeable and all parts are replaceable.

So if you want to expand your grow op, you won’t need a whole new light mover system—just upgrade the LightRail you already have. You can easily add lights, add new track, upgrade the motor, replace anything that wears out. No built-in obsolescence here.

Low-Cost Light Mover

The LightRail 3.5 grow light mover system is the cheapest, entry-level model available from Gualala and should suit the majority of indoor growers—grow tent, grow room, or greenhouse.

The complete kit consists of a two-piece two-meter (6’6”) rail, a 10RPM motor, installation hardware, a 2-year warranty, and clear, detailed instructions (PDF).

If you’ve got a relatively tight grow space, you can use just one-half of the rail, and it’s up to you where along it you place the stopping points. The motor will move your light along your chosen distance at a fixed 4 feet per minute. However, the delay is adjustable, from 0 to 60 seconds, to ensure your light pauses long enough at each end to give even coverage. Without any upgrades or extras, the LightRail 3.5 will expand a 4’x4’ light footprint up to 4’x8’.

Upgrades and extras include Rail Hanger Brackets for easy mounting on grow tents and in greenhouses and the Add A Lamp Kit to allow driving up to 3 lights per rail. The basic kit will support 35lbs of lights, so if adding extra lights takes you above that weight, you might also need the Extreme Duty Trolley Wheels upgrade for heavier lights (up to 60lbs per set). These have a lifetime warranty.

The system draws only 5.5W at the wall. So you can see why we said earlier that running costs are negligible and likely to be covered by improved yields and better light performance.

Downsides?

Not many. If you want to run two lights next to each other, rather than in-line, you’ll need to run two parallel tracks. It doesn’t work on 220V electricity systems. And for larger spaces, having an adjustable speed motor would be handy….

This is where the 4.0 model comes in.

Editor’s Choice: LightRail 4.0 AdjustaDrive Kit

- Light Rail performs over many years like a workhorse with the power and endurance for any light at any weight. Beware of cheaply made imitations.

- Light Rail, solidly made in the USA by Gualala Robotics for continuous-use endurance, with instrument quality and commercial standards. Self-clutch drive design for automatic traction control, advanced digital control circuitry.

- Includes Light Rail 4.0 AdjustaDrive motor, two-piece 6 ft 6 inch in total rail, adjustable travel distance, adjustable speed, adjustable time delay. Compatible with 110v-240v.

- Light Rail, uniquely able to move the larger grow lights, and that is with the Light Rail RoboBar, purchased separately.

- Light Rail has these electrical details c csa us or ce, and flammability proof ul 5 vb, and is rohs compliant, safety standards unique to the Light Rail brand.

- Much better yields when our grow lights move because more leaf area is reached with better light, so no hot spots and no shadow patterns. Plus we can cover significantly more area per grow light, and that's with robotic efficiency.

The LightRail 4.0 AdjustDrive Kit is much like the 3.5 but has an adjustable speed motor (2 to 4 feet per minute) and can work on both US and European electrical systems.

While the 3.5 will suit most growers, we’ve chosen the 4.0 as our Editor’s Choice because the adjustable motor speed offers that extra bit of flexibility.

Being able to control both the delay and motor speed settings means you can get the most out of grow lights of all different intensities on a wider range of different track lengths. So this system could see you right for years, as you improve your growing and upgrade lights.

If you already have the 3.5 Kit and you want that extra customizability, no problem, you can keep your existing setup and just upgrade to the 4.0 AdjustaDrive motor.

And finally, a 4.20 kit is also available, with Extreme Duty Trolley Wheels pre-installed, an extra 2 meters of track pieces, and the Add A Lamp kit included.

The only real downsides to the 4.0 or 4.20 LightRail Kits are that a) electricity consumption is higher (9W); and b), like the 3.5, running lights in parallel rather than in-line means running them on separate parallel tracks.

And once again, that’s where the next model up comes in…

Best Commercial Grow Light Mover System: LightRail RPM

- Light Rail performs over many years like a workhorse with the power and endurance for any light at any weight. Beware of cheaply made imitations.

- Light Rail, solidly made in the USA, manufactured by Gualala Robotics for continuous-use endurance, with instrument quality and commercial standards. Self-clutch drive design for automatic traction control, advanced digital control circuitry.

- Light Rail 5.0 is built to move 2 grow lights side by side. Includes a Light Rail 5.0 motor, a two piece 8 ft rail in total, aux trolley, adjustable crossbar, adjustable travel distance, adjustable time delay.

- Light Rail 5.0 includes a high torque 4rpm instrument grade drive motor with ball bearing output shaft and sure grip dual drive design. Works with North American electrical.

- Light Rail has these electrical details c csa us or ce, and flammability proof ul 5 vb, and is rohs compliant, safety standards unique to the Light Rail brand.

- Much better yields when our grow lights move because more leaf area is reached with better light, so no hot spots and no shadow patterns. Plus we can cover significantly more area per grow light, and that's with robotic efficiency.

The LightRail RPM Kit is Gualala’s top-end commercial grow light mover system. Most of our readers won’t need it, so we’ll keep this summary short.

But for those who are interested…

LightRail RPM can carry up to 90lbs of lights per crossbar and in various configurations, including side-by-side, fore-and-aft, and combinations thereof. One system, with its high torque 4RPM motor, can carry up to 9 lights.

Besides the even stronger construction—backed up by a limited lifetime warranty—and crossbar options, the other main differences here are that the 5.0 comes with a two-piece 8-foot track as standard, motor speed is non-adjustable and electricity consumption is lower than the 4.0 and 4.20—just 5.5W.

Apart from the added expense, the main downside to the RPM is that it’s not backwards compatible with the older models.

Also, crossbars make things a little more complicated—such as balance or accommodating vent tubing when using HID lights.

An adjustable motor speed might have been good too. But arguably the RPM is intended for a more specific use scenario (commercial high-intensity lights as standard), so the more limited customizability is an acceptable sacrifice.

The low budget options

A few cheaper options are available on Amazon and eBay if you’re on a really tight budget, but we don’t particularly recommend them—and nor do a lot of the customer reviews.

While there are a few different brand names out there, when you look closely, the actual products all look virtually identical. The mover comes with a two-piece 7’ rail, that you can also cut down to size, a 10RPM motor, and adjustable delay settings (0 to 120 secs).

So we’re guessing that these are all basically the same product, made by the same factory, but white-labeled by different sellers.

However, we still prefer the LightRail 3.5 to any of these cheaper light movers.

MaryJane’s Advice on Light Movers

Grow light movers get your lights as close to your plants as possible, extend and even out the footprint, lower your lighting costs, and increase yields.

And they’re surprisingly affordable too—especially compared to upgrading your lights or buying additional ones. Well within the budget of most home growers.

If you want to get the most out of your existing lights and grow space, they could be exactly what you need. If you are a serious grower and want to increase your number of plants without increasing your grow space, light movers can often do the trick.

MaryJane Farmer’s recommendation:

Just look for LightRail from Gualala Robotics and choose the system that best suits your setup and budget.

And for even better results, try combining a light mover with plant training techniques.

Have you used grow light movers? Is there one you’d recommend that we haven’t covered here? Any tips? Write MaryJane Farmer and send some photos in the electric mail: MaryJane@420Beginner.com.

Last update on 2023-02-20 / Affiliate links / Images from Amazon Product Advertising API

This product was presentation was made with AAWP plugin.